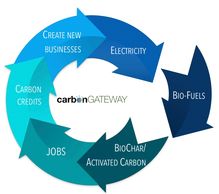

Bio-economic Model

Why this model

carbonGATEWAY projects are being structured with an eye to the impact on the local economic and environmental eco-systems.

Techno-economic Analysis and Life Cycle Assessment studies by private and government entities have shown that building sustainable and resilient enterprises in the bio-economy will require long horizon sources of feedstock and, in most cases, relatively nearby off-take markets for products converted from that feedstock.

carbonGATEWAY is targeting projects that have an inner radius of 50 miles and an out radius of 100 miles. Within these two circles there needs to be sufficient biomass (ag or forest), end-of-life tires, MSW or plastic to support the project.

The next critical element is the conversion technology. This must be modular, potentially mobile,, adaptable to a wide variety of feedstocks, and provide economic output. There are a number that do just that. carbonGATEWAY will remain flexible in selecting the appropriate technology for the specific location of the project with regard not just to being profitable but to bringing economic benefit to the community at large.

Accomplishing these goals will be possible only if the local project managers have the decision rights appropriate to effective and efficiently make them happen. There the Precision Waste Conversion role is to create a framework within which the project is to operate but not the day-to-day decision process.

The framework should allow decision makers to maintain no more than 2 or 3 degrees of separation from any part of the value chain - feedstock supplier, production operations, off-take customers and community leadership.

Learn More

The examples below are based upon common performance paratmeters from a number of pyrolysis and gasification technologies. The carbonGATEWAY model affords the flexibility to select the best location specific technology.

WHAT WE DO

Grid or micro-grid electricity

Grid or micro-grid electricity

Grid or micro-grid electricity

Carbon Gateway systems produce

2.5 MW to 5 MW per ton of feedstock.

This can be used to supply electricity to 5,000 - 10,000 homes or used within an industrial park.

Micro-grids are capable of offering preferred rates to end-users.

Advanced Bio-Fuels

Grid or micro-grid electricity

Grid or micro-grid electricity

Carbon Gateway systems produce an average of 84 gallons of synthetic fuels per ton of feedstock.

A wide range of low carbon intensity fuels can be derived from this syngas produced oil —

Marine fuel

Drop in diesel

Gasoline

Aviation fuels.

These can be used for local fleets at reduced costs while accruing carbon credits.

BioChar, Activated Carbon

Grid or micro-grid electricity

BioChar, Activated Carbon

Carbon Gateway systems can be set to produce an average of 600 pounds of carbon material per ton of feedstock.

This carbon material can be used directly as a bio-char, refined to make activated carbon or carbon black.

These materials can be exported or used regionally for soil amendment, water filtration and an infinite number of other applications.

Jobs

Carbon credits, green image

BioChar, Activated Carbon

The Community Multiplier Effect for Carbon Gateway Florida’s Lake City project will be 2,885 jobs impacted during the build out phase.

The ongoing jobs created will be in the 200 range based on initial plant deployment.

The overall impact of the project is to infuse upwards of $500M into the local economy.

Source:: US DoE Economic Multiplier Model, pyrolysis process.

Carbon credits, green image

Carbon credits, green image

Carbon credits, green image

Carbon Gateway systems allow end-users access to a variety of credits related to climate change initiatives:

RFS, LCFS, New market tax credits and more..

Additionally credits accrue for using waste materials:

End-of-life, scrap tires

Agriculture plant residues

Agriculture animal residues

Forest residues

Municipal Solid Waste

Green yard Waste

Tree trimming service waste

Sludge.

New business creation

Carbon credits, green image

Carbon credits, green image

Carbon Gateway systems can be designed to convert waste material into new materials that can be used for the local/regional manufacturing of products.

This provides an opportunity for the creation of new businesses.

As a member of the local/regional community, Carbon Gateway can assist entrepreneurs in this effort.

Copyright © 2023 Precision Waste Conversion - All Rights Reserved.

Powered by GoDaddy Website